The Holy Grail of high performance

Thu, 28 Jun 2012 09:02:00 BST

Huddersfield researchers seek the answers most sought by industry and engineers

IN the high-pressured world of production engineering there is one piece of knowledge that is precious above all others. How long can valuable machinery continue to work efficiently before the risk of an in-service failure becomes too great?

Now a network of research groups at the University of Huddersfield, linking scientists in a wide variety of disciplines, is taking diagnostic engineering and maintenance to new levels,

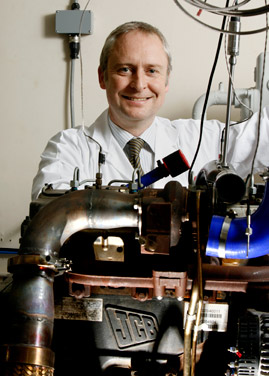

The Centre for Efficiency and Performance Engineering is headed by Professor Andrew Ball (pictured).

“If you are a production engineer you want to make your assets last as long as possible,” he explains. “But you don’t want to run the risk of unnecessary failure. You need to estimate remaining useful life within a given risk. It is the holy grail of reliability and maintenance – what is the remaining useful life of the asset?”

Initially, Professor Ball established a Centre for Diagnostic Engineering at the University of Huddersfield.

But when its remit and range of expertise broadened, it was decided to create the Centre for Efficiency and Performance Engineering as the umbrella for four research groups covering fields that include condition monitoring, automotive engineering, emissions, biofuels, fault diagnosis and prognosis, measurement systems, aerodynamics and marine engineering.

The Centre lists at least 50 research areas between its four groups, which between them have a membership of some 35 academic and research staff, backed by a lengthy roster of research students.

There is a strong international dimension too, as the reputation of the University of Huddersfield in the field continues to attract high calibre researchers.

New arrival brings the Grail closer

A recent arrival is Vietnamese-born Dr Van Tung Tran (pictured), a research fellow attached to both the Measurement Systems and Data Analysis and the Condition Monitoring and Diagnostics Research Groups.

Dr Tran comes to Huddersfield from Pukyong National University in South Korea, where he obtained his postgraduate qualifications and carried out cutting-edge research in fault detection and diagnosis that brings Professor Ball’s “holy grail” ever closer.

For example, Van Tung Tran has worked on the use of artificial intelligence and data-driven techniques to diagnose and prognose failures in machines.

He has also carried out important research in the use of thermal image analysis to provide near-instant information about incipient problems in a machine.

Professor Ball appraises some of Dr Tran’s recent work: “He takes conventional maintenance approaches like thermal imaging and he applies artificial intelligence to automate them, to make them more sensitive and to permit not only detecting of faults but how severe they are.”

He can then offer a prognosis, which means a production engineer can gain invaluable knowledge of how much useful life is left in a machine.

Professor Ball, who is also the University’s Pro-Vice Chancellor for Research and Enterprise, stresses that the work of all the scientists who work under the aegis of the Centre for Efficiency and Performance Engineering is geared to real-world demand and practical problems.

“Everything is user-led,” he says. “We don’t do blue sky thinking!”