New-developed surface crack measurement device aids rail industry

Wed, 22 Jun 2016 11:33:00 BST

The hand-held detection device could extend the life of wheelsets and lead to cost savings of up to 25 per cent

WEAR and tear to the wheels of rolling stock accounts for a large proportion of the maintenance costs for rail operators. Now a hand-held device, developed by an innovative technology company and validated by experts at the University of Huddersfield, has the potential to greatly extend the life of wheelsets, leading to cost savings of up to 25 per cent.

WEAR and tear to the wheels of rolling stock accounts for a large proportion of the maintenance costs for rail operators. Now a hand-held device, developed by an innovative technology company and validated by experts at the University of Huddersfield, has the potential to greatly extend the life of wheelsets, leading to cost savings of up to 25 per cent.

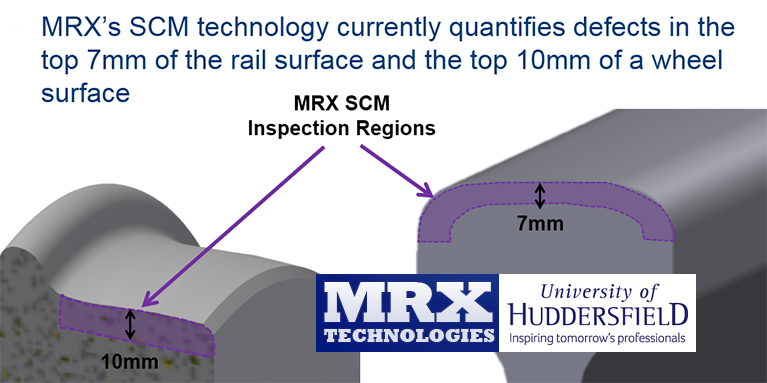

Derby-based MRX Technologies has pioneered technology known as Surface Crack Measurement (SCM). It uses the process termed magnetic flux to detect damage and is well-established for its use in detecting defects in rails. Now the company has produced a hand-held SCM device that can be used to carry out accurate and rapid assessments of the severity of wheel tread damage.

Derby-based MRX Technologies has pioneered technology known as Surface Crack Measurement (SCM). It uses the process termed magnetic flux to detect damage and is well-established for its use in detecting defects in rails. Now the company has produced a hand-held SCM device that can be used to carry out accurate and rapid assessments of the severity of wheel tread damage.

It generates a map of the wheel tread damage, at depths of up to 10mm, which indicates precisely how much material it is necessary to remove during re-profiling on a wheel lathe in order to remove the damaged material, ensuring the safety and prolonging the life of the wheelset.

SCM can act as a replacement to long-standing methods of visual inspection - by which it is not possible to establish the depth of damage - and it promises big gains in efficiency when wheelsets are re-profiled. For example; the use of SCM eliminates the possibility of removing more material than necessary, so that wheels have a longer life before they are discarded.

Also, the crucial balance between removal of sufficient material to eliminate damage and minimising the depth of cut in order to preserve rim thickness is more easily achieved using SCM, and the efficiency of the process means that rolling stock is kept out of service for less time.

The University of Huddersfield is home to the Institute of Railway Research (IRR). It includes a Centre for Innovation in Rail, which has a remit to support companies in bringing innovative products into the rail sector. The IRR’s Head of Enterprise, Dr Adam Bevan, (picured left) supported MRX Technologies in bidding for funding through the Rail Operator Challenge Competition that was being run by RSSB’s Future Railway Programme. This resulted in funding for an 18-month project in which the handheld SCM device was further developed by MRX Technologies and validated by the IRR through a series of wheel lathe trials and laboratory assessments of damaged wheels.

The University of Huddersfield is home to the Institute of Railway Research (IRR). It includes a Centre for Innovation in Rail, which has a remit to support companies in bringing innovative products into the rail sector. The IRR’s Head of Enterprise, Dr Adam Bevan, (picured left) supported MRX Technologies in bidding for funding through the Rail Operator Challenge Competition that was being run by RSSB’s Future Railway Programme. This resulted in funding for an 18-month project in which the handheld SCM device was further developed by MRX Technologies and validated by the IRR through a series of wheel lathe trials and laboratory assessments of damaged wheels.

Dr Bevan said that during the project, the University of Huddersfield’s IRR team supported MRX in using the SCM device to conduct a series of trials on in-service vehicles, scanning the wheelsets before they were put on the lathe to confirm the depth of damage reported by the SCM device.

The Institute were also supplied with a quantity of wheelsets that had been taken out of service. These wheels were scanned with the SCM device prior to sectioning in the laboratory to confirm the accuracy of the damage reported by the device. “The results from these investigations have been conclusive and the technology is proven,” said Dr Bevan.

The project is nearing its conclusion, and Dr Bevan, with Stephanie Klecha, (pictured right) who is UK Engineering Manager of MRX Technologies, have prepared a detailed presentation that summarises the science behind magnetic flux and the performance of SCM when used to inspect wheel tread damage. The paper has been presented to the Institute of Mechanical Engineers in London. It includes case studies and an appraisal of the potential benefits of using SCM for wheelsets, including the prospect of a 25 per cent cost saving.

The project is nearing its conclusion, and Dr Bevan, with Stephanie Klecha, (pictured right) who is UK Engineering Manager of MRX Technologies, have prepared a detailed presentation that summarises the science behind magnetic flux and the performance of SCM when used to inspect wheel tread damage. The paper has been presented to the Institute of Mechanical Engineers in London. It includes case studies and an appraisal of the potential benefits of using SCM for wheelsets, including the prospect of a 25 per cent cost saving.

Stephanie Klecha said: “MRX has been offering the SCM technology for rail defect inspections for nearly 10 years. We are excited to launch the use of SCM for assessing wheel defects. The work we have conducted with the University’s Institute of Railway Research has been invaluable in validating and tuning the hand-held SCM product for turnkey use in depots across the UK.”

The SCM product range, including the new hand-held device, will be displayed at the Innotrans exhibition in Berlin (20th – 23rd September).