Hudds joins €6.2 million European machine tool project

Fri, 27 Sep 2013 13:48:00 BST

Multi-national research project to double lifespan of machine tools

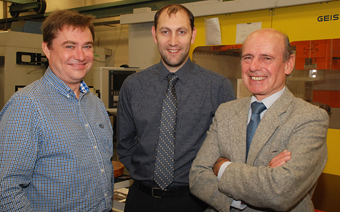

Pictured l-r: Dr Andrew Longstaff, Dr Simon Fletcher and Professor Alan Myers will be leading the development of one module of the three-year EASE-R3 project.

Pictured l-r: Dr Andrew Longstaff, Dr Simon Fletcher and Professor Alan Myers will be leading the development of one module of the three-year EASE-R3 project.

A LARGE machine tool can cost a company many hundreds of thousands of pounds, so potential savings are enormous if its working life can be extended. The University of Huddersfield is playing a key role in a multi-million pound research project that could result in machines doubling their lifespan.

The project is funded by the European Union’s Seventh Framework Programme (FP7). Its total cost is 6.2 million euros. Fourteen partners, including universities, research institutes and engineering companies throughout Europe, are talking part. Huddersfield is the sole UK university to be involved – the University of Huddersfield is the home to the EPSRC Centre for Innovative Manufacturing in Advanced Metrology, which is part of the internationally-renowned Centre for Precision Technologies.

Named EASE-R3, the research is co-ordinated by the Italian engineering firm Fidia. It has been a frequent collaborator with metrologists at the University of Huddersfield and invited them to take part in the new project.

Named EASE-R3, the research is co-ordinated by the Italian engineering firm Fidia. It has been a frequent collaborator with metrologists at the University of Huddersfield and invited them to take part in the new project.

Dr Andrew Longstaff, Dr Simon Fletcher and Professor Alan Myers are the University of Huddersfield experts who will be leading the development of one module of the three-year EASE-R3 project, the overall goal of which is to increase the longevity of CNC machine tools by developing new and cost-effective systems for repair, renovation and re-use.

Depending on its size and how heavily it is used, a machine – possibly costing half a million pounds – could last for up to 10 years.

“The goal of EASE-R3 is to double that lifespan,” said Dr Longstaff. “The carcass of the machine probably won’t be damaged after years of use, but it becomes necessary to replace the drive systems and all the components that can wear down and need to be repaired.

“The goal of EASE-R3 is to double that lifespan,” said Dr Longstaff. “The carcass of the machine probably won’t be damaged after years of use, but it becomes necessary to replace the drive systems and all the components that can wear down and need to be repaired.

“Not only would better maintenance and repair mean cost savings for a company, but there would also be wider environmental benefits, resulting from the reuse of parts and lower energy consumption,” added Dr Longstaff.

EASE-R3 aims to develop new models for maintenance and repair and the University of Huddersfield team will take the lead on the design and prototype production of a compact module, incorporating laser technology that can be fitted to a machine tool to ensure that it retains its accuracy at the point of renovation.