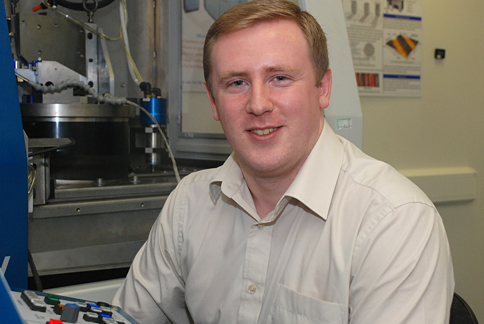

Hudds PhD researcher wins 2015 euspen student challenge

Huddersfield engineer Christian Young (right) with teammates Alberto Figueroa (left) and Hüsnü Aslan (centre).

Huddersfield engineer Christian Young (right) with teammates Alberto Figueroa (left) and Hüsnü Aslan (centre).

Tue, 11 Aug 2015 01:00:00 BST

In just nine hours, Christian Young’s team designed and built a fully-functioning device capable of carrying out a precision 2D measurement, accurate to within 13 microns

UNIVERSITY of Huddersfield PhD student Christian Young (pictured right) was victorious when he went to Stockholm to take part in a major competition to find Europe’s most promising young researchers in the field of precision engineering. In a race against the clock, he and his multi-national teammates constructed a fully-functioning optical measuring machine from scratch and then gave a detailed presentation to the panel of judges.

UNIVERSITY of Huddersfield PhD student Christian Young (pictured right) was victorious when he went to Stockholm to take part in a major competition to find Europe’s most promising young researchers in the field of precision engineering. In a race against the clock, he and his multi-national teammates constructed a fully-functioning optical measuring machine from scratch and then gave a detailed presentation to the panel of judges.

And Christian says that he owes his success not only to the engineering expertise acquired at the University of Huddersfield, but also to his background – unusual for a scientist – as a fully-trained musician.

“It is an unusual transition, from music to engineering,” he admits, “but it has served me well. I like giving presentations because I consider them another form of performance!”

The challenge

The event in which he triumphed was the 2015 euspen Challenge. Organised by European Society for Precision Engineering and Nanotechnology, it seeks to identify the students across Europe who have the potential to be future leaders in the field.

After taking part in a UK national heat held at the Milton Keynes base of sponsoring company Hexagon Metrology, Christian was selected for the European final, held at KTH Royal Institute of Technology in Stockholm. There he was placed in a team with Hüsnü Aslan, from Aarhus University in Denmark and Alberto Figueroa from the University of the Basque Country in Spain.

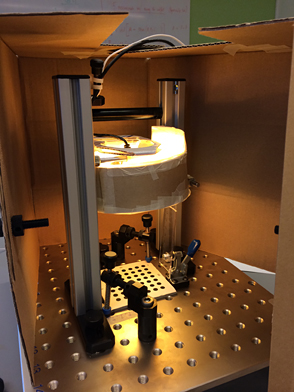

The brief was to construct an optical co-ordinate measuring machine (pictured left) from a basic set of components that included a basic webcam, some LED lights and assorted materials, including cardboard and sticky tape. In the course of nine hours, Christian’s team designed and built a fully-functioning device capable of carrying out a precision 2D measurement, accurate to within 13 microns.

The brief was to construct an optical co-ordinate measuring machine (pictured left) from a basic set of components that included a basic webcam, some LED lights and assorted materials, including cardboard and sticky tape. In the course of nine hours, Christian’s team designed and built a fully-functioning device capable of carrying out a precision 2D measurement, accurate to within 13 microns.

Next day, the trio had two hours to draft a presentation.

“That was another reason we did well,” said Christian. “We had to present the idea, explain technical aspects and come up with a business case for the machine.”

Judges declared Christian’s team as the overall winner of the 2015 euspen Challenge. The three young scientists earned not only the prestige of victory in a premiere contest, but they also each received a MacBook computer.

Switching courses

Christian, aged 28, is from Pontefract and a musical family. He trained as a classical pianist and came to the University of Huddersfield to start a music degree. But, with science subjects among his cluster of A-levels, he decided to switch courses and earned a Distinction for his Master’s in Engineering (MEng). This was a five-year course that included a work placement at the BAE Systems plant in South Wales.

Christian moved straight on to PhD study, supervised by the leading metrologist Professor Liam Blunt, a director of the University of Huddersfield’s EPSRC Centre for innovative Manufacturing in Advanced Metrology.

Shortly to embark on the third year of his doctoral research, Christian is investigating ultra-precision grinding as a method for producing structured functional surfaces.

“At the moment, surfaces with micro-scale geometries are usually manufactured by individually machining each feature using techniques such as micro-milling or lasers. It’s very long, arduous process,” said Christian. “I am looking at using a grinding process to do it in one operation and produce a large area, which will be much more economical.”

Meanwhile, he has no regrets about his unusual trajectory as a student.

“I quickly realised that as much as I love music, it’s not the career I wanted. Switching to engineering is the best decision I have ever made and I have never looked back.”

He now aims for a future working in industry as a researcher on the cutting-edge of high-precision engineering.